Views: 0 Author: Site Editor Publish Time: 2025-11-18 Origin: Site

As electric vehicles (EVs) continue to rise in popularity, efficiency is more important than ever. But have you ever wondered how gears play a role in this shift? In this article, we’ll explore the vital role gears, particularly spur gears, play in EVs. We’ll discuss how these gears help improve efficiency, power transmission, and performance in modern electric vehicles.

Spur gears are crucial for transferring power efficiently between electric motors and wheels. They help achieve over 95% efficiency, reducing energy loss and boosting vehicle performance. Their simple design allows for smooth and consistent torque delivery, optimizing speed and minimizing battery consumption.

Spur gears also play a key role in supporting essential systems like electric power steering (EPS) and regenerative braking. In EPS, they help convert electric motor energy into steering force, making the vehicle easier to handle. During regenerative braking, spur gears assist in converting kinetic energy into electrical energy, which is then stored back in the battery, enhancing overall energy efficiency.

For vintage electric vehicles, spur gears are vital in combining modern performance with classic design. They help provide smooth acceleration, allowing these retro-styled vehicles to maintain their nostalgic driving experience while benefiting from the improved efficiency and reliability of modern electric powertrains.

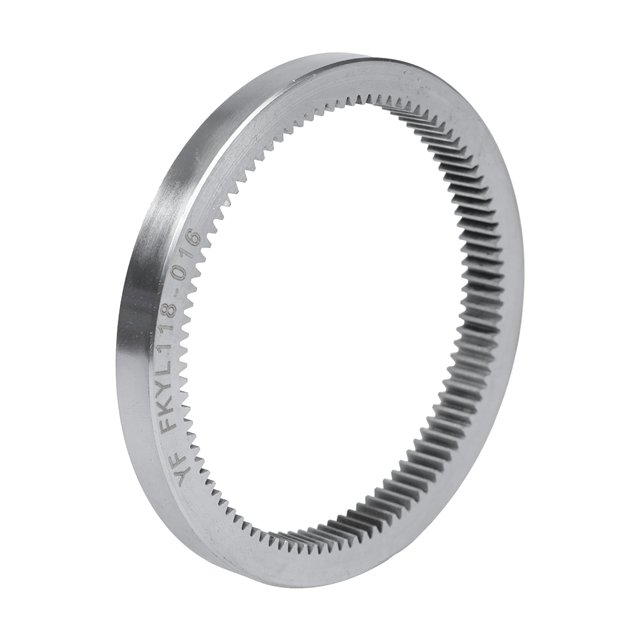

To meet the growing demands of electric vehicles, spur gears are now being made with lightweight alloys and advanced composites. These materials help reduce the overall weight of the vehicle, improving energy efficiency. By using materials like aluminum, titanium alloys, and high-strength composites, manufacturers can cut down on mass while still maintaining the durability and strength of the gears. This not only boosts vehicle performance but also extends the battery range, which is crucial for EVs.

Electric vehicles are known for their quiet operation, and the last thing you want is noisy gears. To solve this, spur gear manufacturers have developed innovative profiling and materials to minimize gear noise. New designs incorporate precise tooth profiles and advanced noise-dampening coatings, which significantly reduce vibrations. This ensures that the vehicle maintains a smooth, quiet ride, even under load.

Innovation | Impact | Example System |

Lightweight Materials | Reduced vehicle weight, enhanced efficiency | EV powertrains |

Noise-Dampening Coatings | Quieter operation, reduced vibration | Electric motors, gearboxes |

Advanced Tooth Profiling | Smoother meshing, less noise | Spur gears in EVs |

One of the key advantages of spur gears in electric vehicles is the ability to customize gear ratios. Using CNC machining and advanced design software, manufacturers can create gears that are tailored to the specific torque and speed requirements of different EV models. Whether it's a compact urban EV, a high-performance sports car, or a heavy-duty electric truck, the right gear ratio ensures that the vehicle operates efficiently at all speeds.

For example, a compact EV may require a higher gear ratio to maximize speed while conserving battery life, whereas a larger EV or electric truck may need a lower gear ratio for better torque and power delivery, especially when towing heavy loads or driving uphill.

CNC machining allows for precise adjustments to tooth profiles, ensuring optimal engagement and smooth power transfer. This customization helps improve overall performance, reduce energy loss, and prolong the life of the vehicle's drivetrain. By fine-tuning gear ratios, manufacturers can meet the exact needs of each EV model, making them more efficient and responsive.

Precision engineering is at the heart of custom spur gear design for electric vehicles. Each electric vehicle model has unique powertrain requirements, and precision engineering ensures the gears are made to fit those needs perfectly. It involves intricate calculations and measurements to ensure the gears mesh smoothly, minimizing friction and wear.

Advanced software programs and CAD designs play a vital role in the customization process. They allow engineers to simulate the performance of different gear designs under various driving conditions. This virtual testing ensures that the gears will perform well even under extreme stress, such as high-speed driving or heavy-duty hauling.

The precision involved in these customizations also helps reduce the noise and vibrations that can be a problem in less refined gear systems. With highly accurate machining and careful material selection, precision engineering ensures that the gears not only meet performance goals but also contribute to the vehicle’s quiet operation.

CNC (Computer Numerical Control) machining has revolutionized gear manufacturing, offering exceptional precision and consistency. By using CNC machines, manufacturers can produce spur gears with incredibly tight tolerances, ensuring a perfect fit for each specific EV model. This technology allows for the customization of gear teeth profiles, improving torque transmission and reducing wear.

The use of CNC machining also makes it possible to produce complex gear designs in a cost-effective way. Manufacturers can produce large quantities of highly accurate gears with minimal waste, reducing both production costs and environmental impact.

Customization Aspect | Impact | Example Application |

Tailored Gear Ratios | Optimizes torque and speed for different EV types | Compact EVs, sports cars, trucks |

CNC Machining | High precision, cost-effective production | Custom gear ratios, profiles |

Precision Engineering | Reduces friction, wear, and noise | High-performance EVs |

Custom spur gears are not just about performance; they also contribute to a vehicle's overall efficiency and longevity. By customizing the gears to meet the specific needs of each model, manufacturers ensure that EVs run at their peak potential, whether they're used for daily commutes or heavy-duty tasks. Precision engineering and tailored gear ratios enhance the driving experience, making it smoother, quieter, and more energy-efficient.

When comparing spur gears to other gear types, such as helical gears, the efficiency of power transmission plays a key role in selecting the best option for electric vehicles (EVs). Spur gears are renowned for their simplicity and high efficiency in transmitting power, often achieving more than 95% efficiency. This is because their straight teeth engage directly, leading to minimal energy loss.

On the other hand, helical gears, while slightly more efficient in certain scenarios, tend to have a higher energy loss due to their angled teeth. This added friction can reduce their overall efficiency, especially in applications where space or cost is a concern. However, the gradual meshing of helical gears does provide smoother operation and can help manage higher loads.

In EVs, where efficiency is crucial for maximizing battery range, spur gears are generally preferred for their cost-effective, energy-efficient performance, especially in smaller or more compact vehicles.

Spur gears are often more cost-effective compared to helical gears. This is because their simple, straight-toothed design makes them easier and cheaper to manufacture. Additionally, the manufacturing process for spur gears doesn't require the precise angles and machining that helical gears do. This lower production cost translates into a more affordable option for EV manufacturers.

When it comes to maintenance, spur gears have the upper hand again. Their straightforward design means they experience less wear and tear, resulting in lower maintenance needs. They don’t require special thrust bearings or complicated lubrication systems, which are necessary for helical gears to handle the axial forces generated by their angled teeth.

Helical gears, though more durable in heavy-duty applications, are generally more expensive to maintain. Their complexity means they require more frequent checks, lubrication, and can be more susceptible to failure under extreme conditions, making them more costly over time.

Gear Type | Efficiency | Manufacturing Cost | Maintenance Cost | Typical Application |

Spur Gears | High efficiency, direct power transmission | Lower due to simpler design | Lower, easy to maintain | Compact EVs, small motors |

Helical Gears | Slightly higher efficiency, smoother meshing | Higher due to complex design | Higher, needs thrust bearings | Heavy-duty EVs, trucks, high-load applications |

Spur gears are ideal for use in compact electric vehicles, electric scooters, and other small EVs where cost, efficiency, and simplicity are essential. Their ability to transmit power with minimal energy loss makes them perfect for these applications, where space is limited, and performance needs to be optimized. Additionally, their low maintenance requirements are well-suited to these vehicles, which often have lower power demands and shorter lifespans compared to larger EVs.

In contrast, helical gears are better suited for heavy-duty electric vehicles and trucks that require more torque and can handle larger, more complex gear systems. Their smoother operation makes them ideal for high-performance vehicles where noise reduction and load-bearing capacity are critical. However, for everyday passenger EVs or smaller vehicles, the added cost and maintenance required for helical gears often outweigh the benefits.

Vehicle Type | Best Gear Type | Reason |

Compact EVs | Spur Gears | Cost-effective, high efficiency |

Heavy-Duty EVs | Helical Gears | Higher torque, smoother operation |

Electric Scooters | Spur Gears | Low maintenance, simple design |

Electric Trucks | Helical Gears | Suitable for high-load, heavy-duty applications |

Tip: Spur gears are the preferred choice for compact EVs, where efficiency and cost-effectiveness are priorities. Helical gears, while offering smoother operation and handling higher loads, are more suitable for larger, more demanding electric vehicles.

As electric vehicles (EVs) become more advanced, integrating smart monitoring systems into gear designs is an emerging trend. These systems allow for real-time tracking of gear performance, including temperature, wear, and load. By using sensors and data analytics, manufacturers can optimize gear performance and prevent issues before they arise.

For example, smart monitoring can detect early signs of wear or stress in the gears, allowing for predictive maintenance. This ensures that EVs remain efficient and reliable, reducing downtime and the need for costly repairs. It also helps extend the lifespan of the gears, which is crucial in an industry focused on longevity and sustainability. As EVs become more connected, the role of smart monitoring systems will only grow, ensuring a seamless driving experience.

The future of gear design in electric vehicles will be heavily influenced by advancements in materials science. To meet the increasing demands for lighter, stronger, and more efficient gears, manufacturers are exploring new materials such as advanced composites, titanium alloys, and carbon fiber.

These materials offer improved strength-to-weight ratios, reducing the overall weight of the gears and, in turn, improving the efficiency of the entire vehicle. For instance, carbon fiber is known for its high strength and low weight, making it ideal for use in high-performance EVs. Additionally, these materials have better resistance to wear and corrosion, ensuring longer-lasting gear systems.

As the demand for more energy-efficient electric vehicles grows, the development of materials that offer superior performance in terms of heat resistance, durability, and lightweight properties will become even more crucial.

Material Type | Key Benefit | Example Use in EVs |

Advanced Composites | Lightweight, strong | Lightweight gears for compact EVs |

Titanium Alloys | High strength, corrosion-resistant | Performance EVs, high-stress applications |

Carbon Fiber | Strong, lightweight, durable | High-performance gear designs |

High-performance electric vehicles (EVs) require specialized gear designs to meet the demands of speed, torque, and overall performance. As the market for electric sports cars and performance EVs grows, gear designs will become increasingly customized to cater to these needs.

Customization will focus on optimizing gear ratios for faster acceleration, smoother shifting, and greater handling of high speeds. Gear profiles will be tailored for maximum torque delivery while maintaining energy efficiency. Additionally, these designs will need to handle the intense demands of performance motors, which require gears that can withstand high rotational speeds and heavy loads.

With the rise of performance EVs, gear manufacturers will use advanced computer modeling and simulations to create highly specialized gear designs. These customized gears will allow performance vehicles to achieve better power transfer, smoother rides, and higher top speeds.

Vehicle Type | Gear Customization Focus | Key Performance Factor |

High-Performance EVs | Gear ratios, torque delivery | Acceleration, handling |

Sports EVs | Precision gear profiles | Speed, efficiency, power |

Luxury EVs | Noise reduction, smooth operation | Comfort, performance |

As the EV industry continues to grow, these trends in gear design will shape the future of electric vehicles, making them more efficient, durable, and tailored to meet the specific needs of drivers. Whether through smart monitoring, advanced materials, or customized designs, the evolution of gear technology will play a critical role in the continued success of electric mobility.

The role of gears in electric vehicles is increasingly important. Spur gears significantly impact EV efficiency and performance. Their simple design leads to high energy efficiency and low maintenance costs. As technology advances, future innovations in gear materials and smart monitoring systems will further enhance EV capabilities. Companies like Yongfeng are leading the way in producing high-quality electric forklift products, which offer durability and efficiency in various industries. Their solutions help businesses optimize operations while ensuring long-lasting performance.

A: Gears in electric vehicles are crucial for transferring power efficiently from the motor to the wheels. Spur gears are commonly used for their simplicity, providing high efficiency and low energy loss.

A: Gears, especially spur gears, help optimize torque and speed, improving the overall performance of electric vehicles while enhancing battery efficiency.

A: Spur gears are cost-effective, easy to maintain, and highly efficient, making them ideal for compact and mainstream electric vehicles.

A: Yes, advancements like smart monitoring systems and the use of lightweight materials are improving gear performance, ensuring longer lifespans and better efficiency in electric vehicles.