Views: 0 Author: Site Editor Publish Time: 2025-08-28 Origin: Site

Choosing a gear type depends on what you need in 2025. Helical gears are good for machines that need to be quiet. They also work well for machines that go fast or carry heavy things. Spur gears are good if you want something simple and cheap. They are reliable for robots and automation. You should think about noise, how well it works, how much it can carry, speed, price, and what you will use it for.

Helical gears are becoming more popular in cars and building machines.

Spur gears are still used a lot in factories because they save energy and use new materials.

Knowing the main differences helps you pick the right gear for your project.

Helical gears are great if you want things to be quiet and smooth. They work well when machines move fast or carry heavy things.

Spur gears do not cost much and are easy to use. They are good for simple jobs. It is easy to make and fix them.

Think about how much noise the gears make. Helical gears make less noise and shake less. This makes them good for places that need to be quiet.

Look at how much weight the gears can hold and how well they work. Helical gears can take more force because of their shape. Spur gears work well for lighter jobs.

Talk to experts like Yongfeng Gear for special help. They can help you pick the best gear and material for your project.

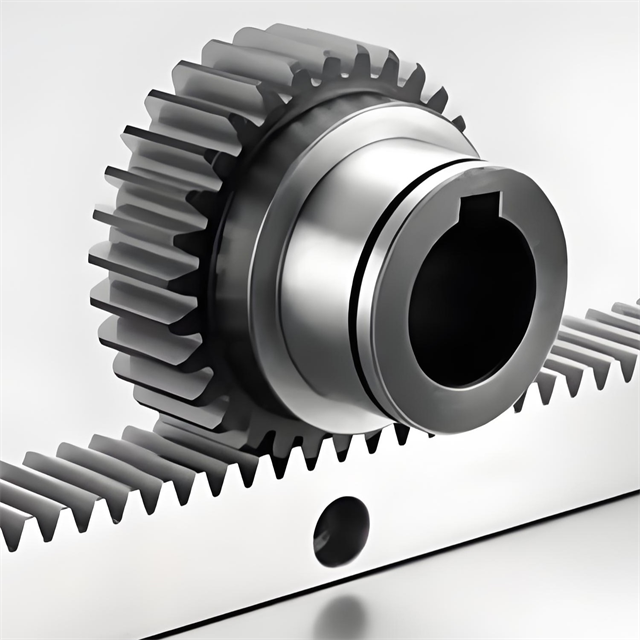

Spur gears are the most common gears in machines. They have straight teeth and sit on shafts that are side by side. Their simple shape makes them easy to make and fix. If you pick a spur gear from YF Gear, you get strong and accurate gears. Yongfeng Gear uses special CNC machines and checks quality to make sure each gear works well for you.

Spur gears can be made from different materials. Steel is strong and lasts a long time. Plastic spur gears are light and good for jobs that do not need much force. Cast iron spur gears cost less and do not rust easily. Stainless steel spur gears do not rust and work well in food or tough places. Aluminum alloy spur gears are strong, light, and easy to shape.

Material | Characteristics |

|---|---|

Steel | Easy to shape, tough, saves money |

Plastic | Light, does not rust, good for small jobs |

Cast Iron | Cheap, does not rust, easy to mold |

Stainless Steel | Does not rust, comes in many types |

Aluminum Alloys | Strong, light, does not rust, easy to shape |

Spur gears have some key features:

Gear ratio changes speed and force.

Module tells you how big the teeth are.

Face width shows how much weight the gear can hold.

Tooth profile, usually involute, helps the gear move smoothly.

YF Gear makes custom spur gears for you. You can pick the size, module, hole, and material. You also get help with design to choose tooth count and pressure angle. Heat treatment makes gears harder and last longer. Surface finishing helps gears run quietly and with less rubbing. Composite materials give you strong gears that are not heavy.

Spur gears are used in many fields. In cars, spur gears help with shifting and engine parts. Big machines use spur gears in belts and gearboxes. Robots use spur gears to move arms and parts exactly. Pumps and compressors use spur gears to spin blades and push pistons. Machine tools need spur gears to move parts in lathes and mills. Power plants use spur gears in turbines and other machines. Farms use spur gears in tractors, harvesters, and water pumps.

Industry | Application Description |

|---|---|

Automotive | Shifting gears, engine parts, steering systems |

Industrial Machinery | Belts, gearboxes, pumps |

Robotics | Moving arms, gear systems |

Pumps & Compressors | Spinning blades or pistons |

Machine Tools | Lathes, mills, grinders |

Power Plants | Turbines, other machines |

Agriculture | Tractors, harvesters, water pumps |

Spur gears give smooth force and work well. They are best for jobs that need medium speed and strong gears. YF Gear spur gears help your machines work better and break down less. You can ask for custom spur gears for your project and get help from Yongfeng Gear’s experts.

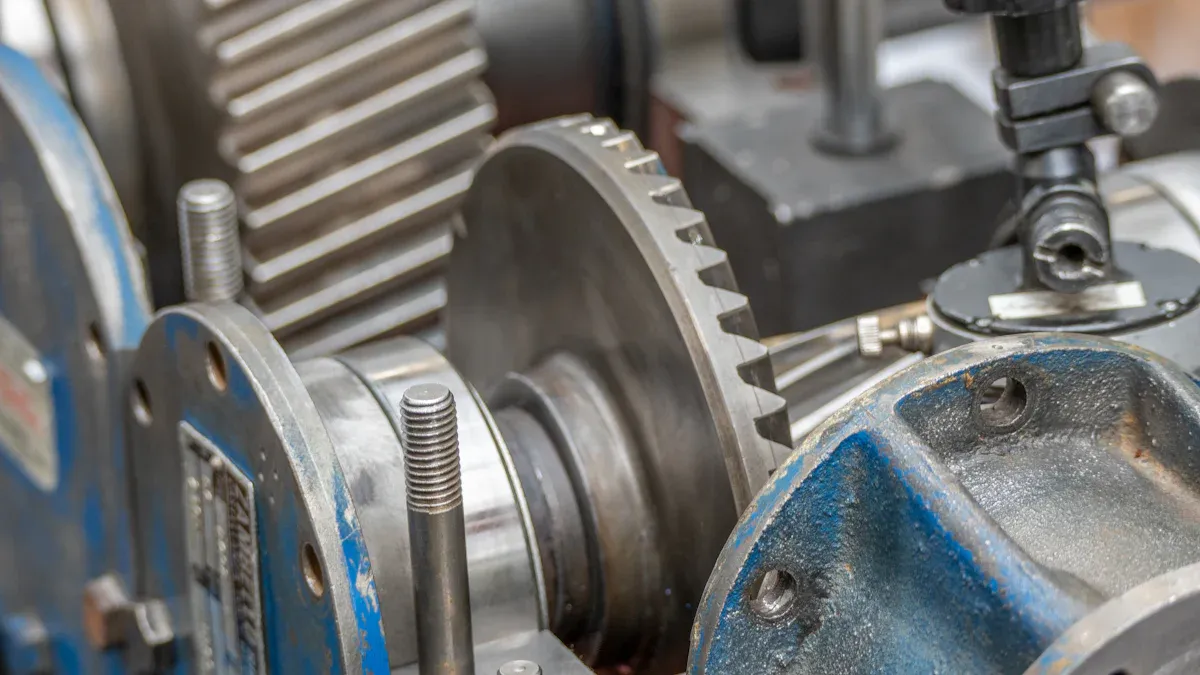

A helical gear has teeth that slant across its face. The teeth make a spiral shape called a helix. This is why it is called a helical gear. The teeth touch each other slowly and smoothly. This makes less noise and less shaking than spur gears. The slow touch also lets the gear handle more force.

Yongfeng Gear uses special machines to make helical gears very exact. You can pick the size, tooth angle, and material you want. They offer steel, stainless steel, and strong plastics. These gears last longer and run quietly.

Here is a table that shows how helical gears and spur gears are different:

Feature | Helical Gears | Spur Gears |

|---|---|---|

Tooth Shape | Inclined teeth forming a helix shape | Straight teeth parallel to the gear axis |

Engagement | Gradual engagement for smoother operation | Sudden engagement causing impact and noise |

Noise and Vibration | Quieter operation due to reduced impact | More noise and vibration due to sudden engagement |

Efficiency | Higher efficiency with reduced sliding friction | Lower efficiency due to higher sliding friction |

Load-Carrying Capacity | Higher load capacity due to larger contact area | Moderate load capacity with smaller contact area |

Backlash | Lower backlash for better precision | Higher backlash affecting accuracy |

Applications | Used in high precision and heavy load applications | Suitable for simpler, less demanding applications |

Helical gears are more accurate and wear out less. The teeth touch over a bigger area, so the gear can carry more weight. There is also less backlash, so the gear moves more exactly.

Helical gears are used where quiet and strong work is needed. These gears are good for machines that must run smooth and carry heavy things.

Helical gears are in conveyors. They help move things quietly and well.

Elevators use helical gears to lift. The gears are strong and make less noise.

Cars use helical gears in gearboxes. This helps with smooth shifting and carrying heavy loads.

Printing machines use helical gears. This keeps them quiet and working right.

Helical gears are in robots and medical machines. They help parts move right and stay quiet.

Tip: If you need a gear for fast or heavy jobs, pick a helical gear. It is quieter and stronger.

You can ask Yongfeng Gear for custom helical gears. The company helps you choose the best gear for your job. You get help from start to finish.

When you look at spur gears and helical gears, you see they work differently. Each gear is better for certain jobs. Here are the main things to think about when picking a gear.

Tooth engagement means how the teeth of two gears meet and move power. This is a big difference between spur gears and helical gears.

Gear Type | Tooth Engagement Characteristics | Impact on Lifespan and Reliability |

|---|---|---|

Helical Gears | Inclined teeth engage gradually, resulting in smoother operation. | Improved load distribution leads to reduced stress, enhancing lifespan. |

Larger contact area during meshing reduces stress concentration. | More reliable under heavy loads due to better efficiency. | |

Spur Gears | Straight teeth engage suddenly, causing impact and noise. | Higher stress on individual teeth can lead to quicker wear. |

Smaller contact area increases the likelihood of failure under heavy loads. | Less reliable in demanding applications. |

Helical gears have angled teeth. These teeth slide into place slowly. This spreads the force over more space. It helps the gear last longer and work well with heavy loads. Spur gears have straight teeth. The teeth hit each other all at once. This puts more stress on each tooth. It can make the gear wear out faster and not work as well for hard jobs.

Efficiency shows how much power a gear can move without losing energy. Both spur gears and helical gears are good at this, but there are some differences.

Gear Type | Efficiency Rating | Characteristics |

|---|---|---|

Spur Gears | High | Cost-effective, high mechanical efficiency |

Helical Gears | Moderate to High | Smoother operation, higher load capacity, higher manufacturing cost |

Spur gears are very efficient. Their simple shape means less sliding, so less energy is lost. Helical gears are also efficient. They are best when you want smooth movement and can accept a little power loss. Standards like ISO 6336 and AGMA 2101-D04 help you check and compare how well both gears work.

Noise and vibration are important if you want your machine to be quiet. How the teeth meet changes how much sound and shaking you get.

Helical gears make less noise and shake less. The angled teeth slide in, so power moves smoothly.

Spur gears make more noise and shake more. The straight teeth hit each other fast, making loud sounds.

Even with a high contact ratio, spur gears are still louder than helical gears.

If you want a quiet machine, pick helical gears. They help lower noise and shaking, so they are good for places where sound matters.

Load capacity is how much force a gear can take before it breaks or wears out. Many things change this, like the angle of the teeth, the width of the gear, and what it is made from.

Helix angle: A bigger angle on helical gears spreads force better, so the gear can carry more. It also makes a side force you need to control.

Pressure angle: A higher pressure angle lets the gear hold more force but can make it rub more.

Face width: A wider gear face lets the gear carry more.

Module: Bigger teeth (higher module) mean the gear can handle more force.

You can pick from many materials. Alloy steels and case-hardened steels make strong gears that last long. Nitrided steels and composite materials are strong and light. Helical gears usually hold more force because their teeth spread the load. Spur gears are good for lighter loads and easy jobs.

Cost is always something to think about when picking a gear. Spur gears usually cost less. Their simple shape makes them easy to make and fix. Helical gears cost more because their angled teeth need special machines and more time to make.

Feature | Spur Gears | Helical Gears |

|---|---|---|

Tooth Design | Straight teeth | Angled teeth |

Engagement | Direct engagement, causing noise and vibration | Gradual engagement, resulting in quieter operation |

Load Distribution | Less effective, leading to higher wear | Better load distribution, reducing wear |

Applications | Common in devices like washing machines | Used in high-speed and high-torque applications |

Gear Ratio Range | 1:1 to 6:1 | N/A |

Cost | Lower manufacturing and maintenance cost | Higher due to complex design and production |

Note: Spur gears save money and work well for simple, quiet jobs. Helical gears cost more but give smoother, quieter, and stronger performance.

Picking the right gear can seem hard. You can make a good choice by thinking about what you need most. Let’s look at which gear works best for each job.

If your machine goes fast, you need strong gears. Helical gears are good for fast jobs. Their angled teeth fit together smoothly. This helps your machine stay quiet and last longer. Spur gears also work for fast machines. They are simple and easy to fix.

Tip: Gear hobbing is a common way to make spur and helical gears for fast machines. This method makes strong gears that work well in big batches.

Think about gear size too. Small gears spin faster but use less force. Big gears turn slower but can hold more weight. Match your gear size and type to your machine’s speed and power.

How to choose for high speed:

Use helical gears for smooth and quiet fast jobs.

Pick spur gears for simple and cheap moderate speed jobs.

Ask Yongfeng Gear for advice. Their team can help you pick the right gear for your speed needs.

Noise can be a problem in machines. If you want quiet machines, pick helical gears. Their angled teeth touch slowly. This means less shaking and less noise. Special materials and careful making can make gears even quieter.

Gear Type | Noise Reduction Features |

|---|---|

Helical Gears | Angled teeth help gears run quietly and with less shaking. |

Precision Manufacturing | Good gear making keeps gears lined up and quiet. |

Profile Modification | Changing gear tooth shape can lower noise and errors. |

Damping Materials | Some materials soak up shaking and lower noise. |

Advanced Composites | New materials can make gears quieter than metal ones. |

Note: Yongfeng Gear makes custom helical gears with special materials and tooth shapes. You can ask for extra quiet features for your needs.

If you need to save money, spur gears are best. Their simple shape makes them cheap and easy to fix. Spur gears also work well and waste less energy. Helical gears cost more because they take longer to make.

Aspect | Spur Gears | Helical Gears |

|---|---|---|

Cost | Cheaper and easier to make | Usually cost more to make |

Efficiency | Work well and save energy | Work well but use more energy |

Durability | Good for short jobs | Last longer and need less fixing |

If you want to spend less and do not need a quiet machine, spur gears are smart. If you want gears that last longer and need less fixing, pick helical gears.

Tip: Yongfeng Gear can help you save money and get good gears. You can ask for custom spur gears made from different materials.

Machines that lift heavy things need strong gears. Helical gears spread force over more teeth. This makes them good for tough jobs. Their shape helps them last longer and run smooth under stress.

You can use sensors to test how much weight your gears can hold. This helps you pick the right gear.

Load Cells

Torque Transducers

Multi-Axis Sensors

Calibration Systems

A new test for gear oils checks how gears handle heavy loads. This helps you pick the best oil and gear for your machine.

Callout: For heavy jobs, ask Yongfeng Gear about custom helical gears. Their team can help you pick the best size, material, and oil.

Summary Table: Practical Gear Selection

Criteria | Spur Gears | Helical Gears |

|---|---|---|

Speed Requirements | Good for fast jobs | Good for changing speeds |

Torque Demands | Good for medium force | Better for changing loads |

Noise & Vibration | Louder | Quieter because teeth touch slowly |

Load Distribution | Medium force spread | Better force spread over teeth |

Cost | Lower | Higher |

Durability | Good for short jobs | Best for long, tough jobs |

No matter what you need, Yongfeng Gear can help. You can get help with design, picking materials, and special features. Their experts help you from start to finish so you get the best gear for your project.

You can choose custom spur gears from Yongfeng Gear to match your exact needs. Yongfeng Gear uses advanced machines to make gears that fit your project. You can select the size, material, and tooth shape. The team helps you design gears for better strength and longer life. You get gears that work well in robots, cars, and machines.

Yongfeng Gear offers a wide range of gear solutions. The table below shows what you can expect:

Gear Solutions Offered | Customer Satisfaction Aspects |

|---|---|

Custom gears | Customer Needs First: Prioritizing customer satisfaction |

Precision gears, racks, timing belt pulleys, | Rapid Response Mechanism: Efficient customer service |

sprockets, worm gears, and worms | Long-Term Partnerships: Building stable relationships |

Flexible Customization Services |

You always get support from the first idea to the final product. The company listens to your needs and gives advice for the best results.

You can also order custom helical gears from Yongfeng Gear. These gears help your machines run quietly and handle heavy loads. You pick the tooth angle, material, and size. The team uses strong steel and special plastics for different jobs. You get gears that last longer and reduce noise.

Yongfeng Gear makes the process easy for you. Here is how you can request a custom gear quote:

Send your gear drawing or tell the team your needs.

Get a quick reply with advice and a price.

The team makes your gears after you confirm the order.

You can contact Yongfeng Gear by phone at +86-19925253785 or by email at Yongfenggear@163.com. The team answers your questions and helps you start your project. You get reliable service and high-quality gears every time.

Picking spur or helical gears depends on what you need. Helical gears are best if you want things to run quietly and smoothly. Spur gears are good for simple jobs and saving money. You should look at some important things before you choose:

Factor | Description |

|---|---|

Gear Axes Configuration | Changes how fast and well the gear works |

Number of Teeth | Affects how fast the gear turns |

Costs | Depends on what it’s made of and if it’s custom |

Smart gear systems help machines work better and stop less.

3D printing makes gears that are light but still strong.

Always pick a gear that fits your machine for the best results.

In 2025, think about what you need and use the table to help you choose the right gear.

You will see that a spur gear has straight teeth. A helical gear has slanted teeth. The teeth shape changes how the gear moves power. Spur gear teeth meet all at once. Helical gear teeth meet slowly and smoothly.

You should pick a spur gear when you want a simple design. Spur gear works well for machines that do not need to run quietly. You can use a spur gear for robots, conveyor belts, or simple gearboxes.

A helical gear has teeth that touch each other slowly. This smooth contact makes less noise. Spur gear teeth hit each other at the same time. This makes a spur gear louder than a helical gear.

You can use both types in one machine. You might use a spur gear for simple parts. You might use a helical gear for parts that need to run quietly. Mixing gear types helps you get the best performance.

You should look at your machine’s needs. Use steel for strong gear parts. Use plastic for light gear jobs. Stainless steel works well in wet places. Ask a gear expert if you are not sure.

Tip: Always match the gear type and material to your machine’s job for the best results.

content is empty!